PRODUCTS DETAILS

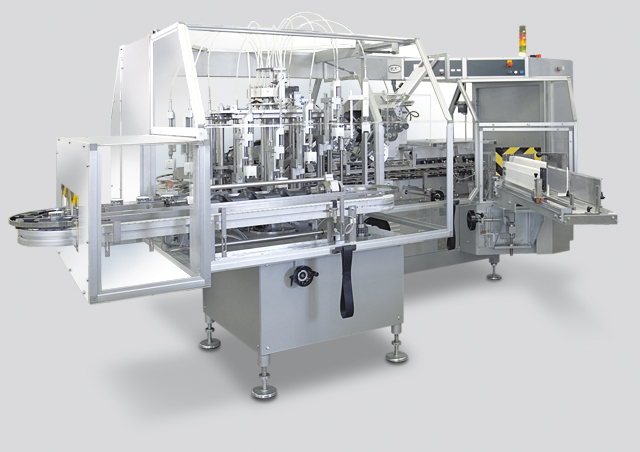

AVC | High speed continuous motion vertical cartoner

The AVC is a continuous motion vertical loading cartoner which reaches up to 300 mechanic strokes per minute.

All movements are controlled by closed-profile cams which have been subjected to surface hardening treatment. This feature, together with the heavy-duty structure, reduce maintenance operations and guarantee a long life of the machine.

AVC is characterized by the exclusive carton erection system incorporating a 4-station turret , each station separately driven by closed-profile cams for carton pick-off at zero speed. This system allows for total and progressive carton pre-breaking.

The wide range of product feeders available covers all possible packaging requirements of the market and is particularly suitable for bottles and jars.

The AVC is also equipped with the Mechanical Memory® system, transforming complete size change-over into a series of rapid and pre-set operations, eliminating the need for fine-tuning adjustments.