Emballage 2010

10 May 2016

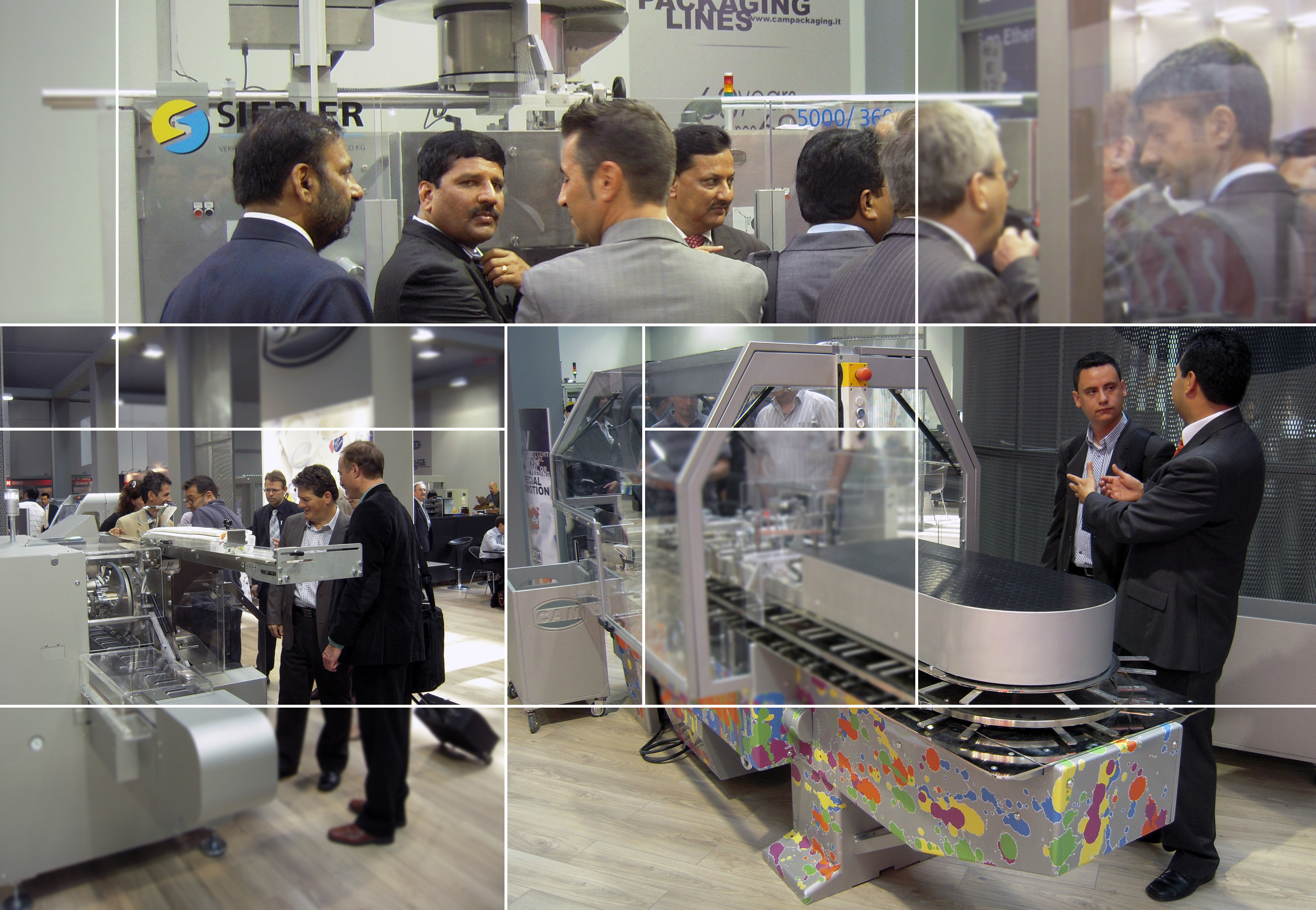

Interpack 2011

10 May 2016CAM has recently developed the ZP-Easy model, a palletizer characterized by its low price, its versatility, and its ability to perform in not optimal working environments.

In particular:

- all commands related to grasping head movement and product positioning have been installed on the top part of the machine. This allows the ZP-Easy to lend itself to use in working environments may they have floors that are dusty, wet, or even corroded by liquids;

- injury-preventive protections have been manufactured in steel grid.

Another important characteristic of the machine is its disposition versatility. In fact, various positioning points of the infeed conveyor are possible (linear, or at a 90° angle both on one side and the other of the machine) and, consequently, positioning of the pallet feeder and the electrical cabinet are also variable. This allows the configuration of the machine to adapt itself to all different types of space requirements.

Furthermore, it is important to underline that:

- the infeed conveyor has a length that allows sufficient “buffering” in the pallet change phase, without the need of increasing machine dimensions;

- the machine, in its standard version, can stack products up to a height of 1800 mm (pallet excluded);

- the operator panel may be interfaced with an external PC in order to carry out automatic configuration of product formats;

- it is possible (upon request) to carry out on-line remote technical support for the machine.

Analogously to the ZP1 model, it is possible to install single or multiple suction-cup or clamp grasping systems on the ZP-Easy as well.

The machine is furthermore predisposed to handle not only case-packs, but even bags of large sizes.